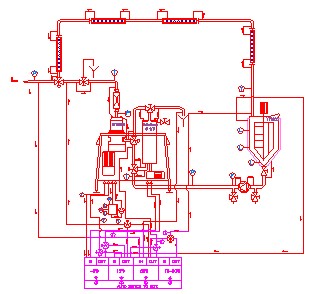

OVERVIEW CHOCOLATE AERATION

PRINCIPLES OF AERATING CHOCOLATE

From the buffer tank (3) the molten chocolate/fat is pumped with the dosing pump (4) through the

Scraped surface heat exchanger (collotherm), where the chocolate forms its first seading-crystals ,which are necessary for the

aeration. The chocolate/ fat cream changes into plastic conditions.

Inside the scraped surface heat exchanger, and the jacketed and temperated piping after the

Colletherm and before the mixing head of the Converticoll , the necessary residence time is

created for further crystal formation and growth to be able to aerate the chocolate/fat compound .

The time will be up to 3-4 minutes.

The plastified chocolate/fat cream now arrives into the continuous aerating head of the Converticoll, where it get its foam and body.

From there the creme is either going to an extruder or depositor.

ASJO Consultants email: info@asjoconsultants.com Phone: +31 (0) 297 344 050

Fax : +31 (0) 297 343 991