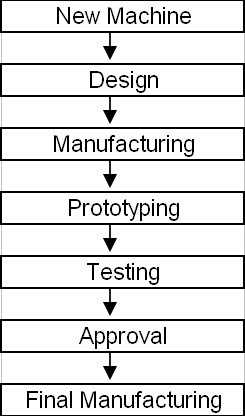

Manufacturing

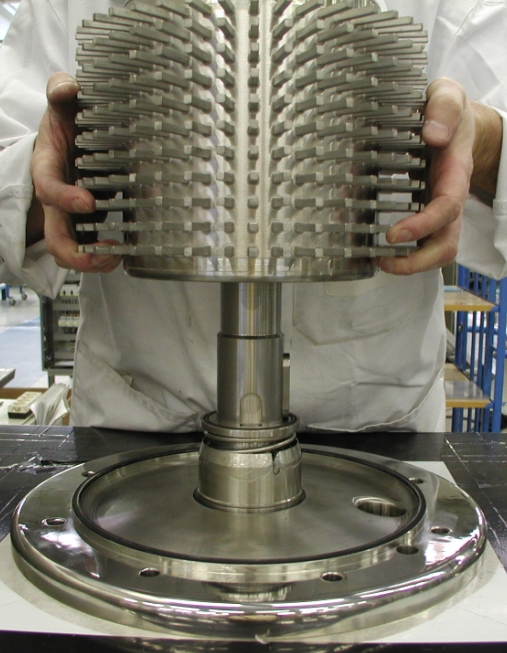

A team of specialists takes all the precautions for the manufacturing of your equipment.

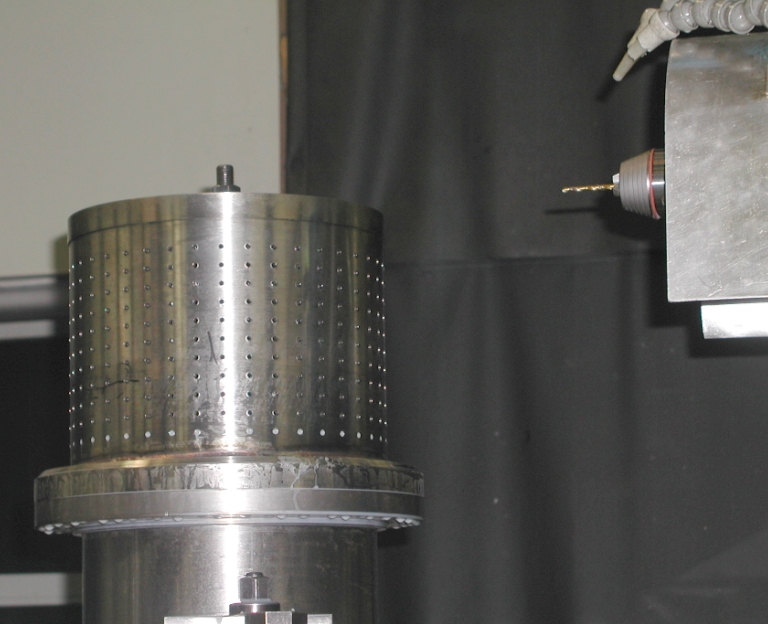

The machining is done in-house.

Once all machines are build the complete installation is assembled together.

Piping, pumps and tanks are built together on a frame.

Welding is done with Tig in jacketed piping.

Once everything is built together the elecrical and pneumatic connections are made and the

installation is tested to ensure all functions are working properly.

Once everything is operating to expectations the customer is invited to attend the FAT (Fat Acceptance Test).

After approval by the customer the installation is disassembled, labelled and packed in crates.

ASJO Consultants email: info@asjoconsultants.com Phone: +31 (0) 297 344 050

Fax : +31 (0) 297 343 991